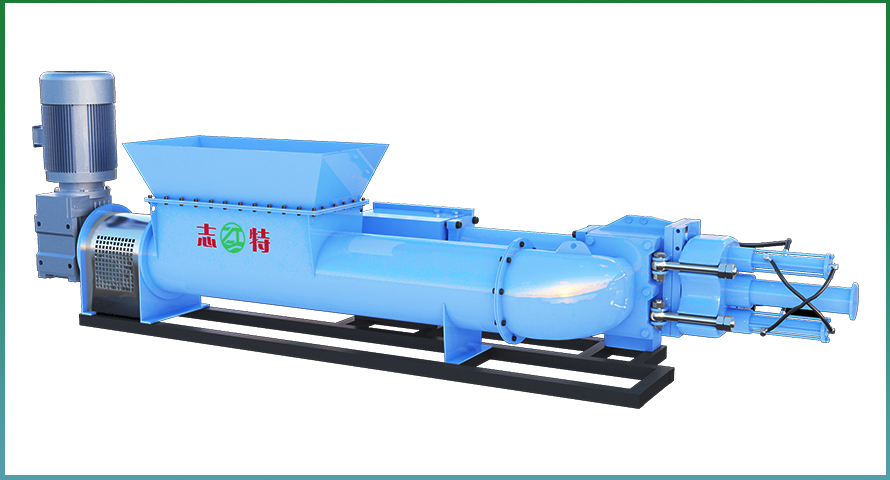

Kitchen waste transfer pump

Equipment introduction

The double cylinder feeding pump is also known as the double cylinder force-feeding kitchen waste continuous feeding pump. Compared with the single cylinder feeding kitchen waste feeding pump, the double cylinder force-feeding kitchen waste continuous feeding pump has the advantages of good material conveying continuity, almost no break point during conveying materials, and large conveying capacity. It is mainly used to transport a large number of kitchen/kitchen waste and other polluting substances in a closed manner. The theoretical outlet pressure of the pump is 20Mpa, the head is 10m, and the horizontal pumping distance can reach more than 70m. The power system of the feed pump is a hydraulic power mechanism, the control mode is PLC program control, and the cylinder block position detection sensing mechanism is equipped.

The equipment is mainly used for food waste, food waste, food waste fruit and vegetable waste, agricultural waste, farmers' market waste, sanitation, garden and other perishable organic waste, and even food waste containing shells, bones, bamboo shells and other hard things. The equipment is generally used in centralized kitchen waste treatment centers and units with strict environmental management (such as: various schools, enterprises and institutions, troops, etc.) and kitchen waste treatment centers of large chain hotels.

Product characteristics

Small footprint, large throughput, high efficiency: the equipment adopts forced feeding screw as the feeding method of the conveying pump, which can ensure that there is sufficient food waste and other materials in the conveying pump pipe every time the cylinder body moves, and the conveying volume under the same equipment is almost twice that of the single-cylinder food waste conveying pump.

Full distance closed transmission, no dripping no odor, small footprint, simple layout, the use of self-designed gate valve reversing, good sealing, long life.

The outlet pressure is high, up to 15Mpa, which can meet the requirements of long-distance transmission, the horizontal transmission distance can be more than 70 meters, and the vertical transmission distance can be more than 10 meters.

Hard chrome plating inside the pump body, can transport hard materials, such as aggregate, shell hard objects, can pump large particles, particle size ≥80mm.

The electrical part is controlled by PLC, and the electrical material box is equipped with remote control and panel dual operation, which is quite convenient.

Equipment parameter

(The dimensions can be redesigned according to the site, please contact the sales staff for detailed parameter configuration) :

Model number | Processing capacity (T/h) | Feed screw diameter (mm) | Pipe diameter (mm) | Horizontal transmission distance (m) | ertical transmission distance (m) | Power (kw) | Overall dimensions (mm) |

ZT-SLB-10 | 6-14 | 180 | 133 | 50 | 10 | 3+15 | 3500*1000*580 |

ZT-SLB-15 | 9-25 | 219 | 159 | 60 | 15 | 4+18.5 | 3700*1000*600 |

ZT-SLB-20 | 20-38 | 273 | 219 | 70 | 15 | 5.5+30 | 3700*1100*620 |

ZT-SLB-30 | 28-46 | 315 | 245 | 60 | 20 | 7.5+37 | 4100*2000*620 |