High temperature steam sterilization process of medical waste

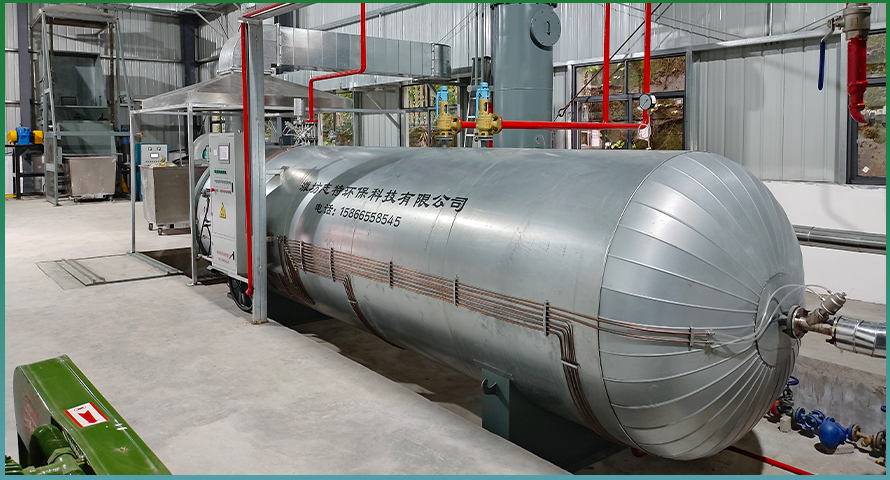

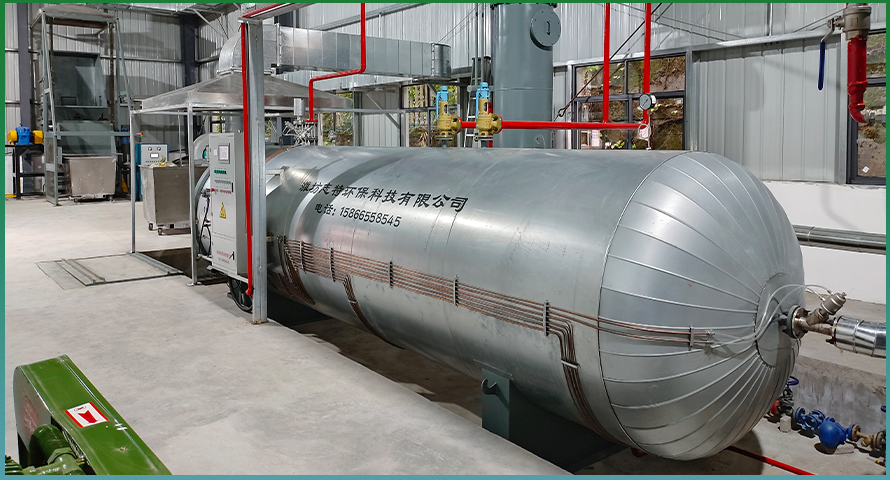

Equipment introduction

High temperature steam sterilization (wet heat sterilization) is a kind of thermal sterilization. Under the influence of high temperature and high humidity, pathogenic microorganisms cause irreversible denaturation and solidification of proteins and enzymes, which leads to the death of microorganisms. So as to achieve the purpose of killing microorganisms. The high temperature steam sterilization process of medical waste takes high temperature saturated steam as the working medium, and uses its strong penetrating power to penetrate deep into the inside of the sterilized articles and release the latent heat contained in the steam, so that the sterilized articles quickly heat up to the sterilization temperature and maintain for a period of time, so that the protein in the bacteria solidify and denature, thus killing all microorganisms including bacterial spores.

Sterilization process

Charge:

The medical waste is poured into the sterilization car specially equipped with the sterilizer through the feeding machine, and then the sterilization car is transported to the sterilizer. After the number of sterilization cars in the sterilizer reaches the set value, close the front door and wait for sterilization treatment. Note: The front and back doors of the sterilizer cannot be opened at the same time. Once the program is running or there is pressure in the chamber of the sterilizer, it is not possible to open or close the door to ensure personal and equipment safety.

Sterilization treatment:

After the front door is closed, PLC gives instructions to the sterilizer to start running the sterilizer's preset sterilization program and carry out sterilization treatment. After entering the sterilization stage, the system automatically timing to ensure the sterilization intensity. In the sterilization stage, the steam main valve and steam auxiliary valve will be opened and closed according to the real-time temperature in the sterilization kettle. Once the temperature in the sterilization kettle is lower than the set sterilization temperature, the steam auxiliary valve will be opened to enter the steam for heating. When the temperature in the sterilization kettle is lower than the set temperature of 1℃ (configurable), the steam main valve will be opened to enter a large amount of steam for heating. When the temperature in the sterilization kettle is higher than the set sterilization temperature, the steam main valve and auxiliary valve are closed, which not only ensures the sterilization temperature but also avoids the steam waste caused by excessive temperature. When the sterilization time reaches the set time, the system moves to the post-vacuum drying stage.

Process flow

The technology of Chite medical waste high-temperature sterilization treatment system adopts the process of sterilization before crushing, which can realize automatic cage conveying, greatly reduce the labor intensity of operators, and better reduce the pollution in the treatment process. The principle of high temperature steam sterilization is to use steam to solidify and denature the proteins of microorganisms and kill them.

1. Feed

Pour the medical waste into the sterilization transfer frame specially configured in the sterilization kettle, and the transfer frame will be automatically transported to the sterilization kettle. When the sterilization kettle is full, close the front and back two sterilization kettle doors and wait for sterilization treatment.

2, sterilization treatment

When the two sterilizer doors are closed, press the "sterilize" key, and the system will automatically sterilize the treatment process. The sterilization treatment is divided into five stages: pre-vacuum cooling, heating, sterilization, post-vacuum drying, drainage and exhaust to ensure the sterilization effect.

3. Discharge and break

After the front door is fully opened, the transmission mechanism in the sterilization tank will automatically send out the transfer frame one by one, and through the turnover of the cage frame conveyor line, it is sent to the elevator, and the elevator will pour the sterilized medical waste into the crusher for crushing. Crushing treatment can not only prevent illegal recycling, but also make subsequent incineration or landfill treatment more convenient.

4. Collection and transportation

The broken waste is sent to the garbage carrier and finally to the disposal site.

Sterilization treatment

1. Pre-vacuum cooling. Driven by steam, the vacuum pump vacuums the air in the sterilizing kettle, at the same time, the extracted air is steam sterilized, the pressure in the sterilizing kettle is pumped to the set negative pressure, to ensure the heat distribution effect during constant temperature sterilization, to ensure that there is no cold point in the sterilizing kettle, so as to better ensure the sterilization effect.

2. Heat up. When the temperature is close to the set temperature, close the steam main valve and open the steam auxiliary valve, which can prevent the danger caused by excessive temperature to the equipment, and at the same time can save the use of steam and reach the sterilization temperature. After the temperature rises to the set temperature, the sterilization stage begins.

3. Sterilization. After entering the sterilization stage, the system automatically timing to ensure the sterilization intensity. In the sterilization stage, the steam main valve and steam auxiliary valve will be opened and closed according to the real-time temperature in the sterilization kettle. Once the temperature in the sterilization kettle is lower than the set sterilization temperature, the steam auxiliary valve will be opened to enter the steam for heating. When the temperature in the sterilization kettle is lower than the set temperature of 1℃ (configurable), the steam main valve will be opened to enter a large amount of steam for heating. When the temperature in the sterilization kettle is higher than the set sterilization temperature, the steam main valve and auxiliary valve are closed, which not only ensures the sterilization temperature but also avoids the steam waste caused by excessive temperature. When the sterilization time reaches the set time, the system moves to the post-vacuum drying stage.

Note: When the temperature in the autoclave is much lower than the set temperature, the steam main valve will open, but at this time, attention should be paid to whether the supply pressure of the steam main pipeline is too low.

4, vacuum drying. First of all, open the vacuum valve, the pressure in the sterilized kettle is discharged, and the steam in the kettle will condense into water in the condenser, which will enter the sewage treatment system, and some steam is not condensed into the waste gas treatment system. When the pressure drops to the set value, the steam driven vacuum pump begins to extract the negative pressure, and the process of vacuuming can not only take away water, but also reduce the temperature to avoid danger. After the vacuum pressure reaches the set value, it will be maintained for a period of time (can be set), and after the duration reaches the drainage and exhaust stage.

5. Drain and exhaust. The vacuum valve is opened, and the air enters the sterilization kettle for pressure balance. When the pressure is close to zero, the drainage valve is opened and the condensate water in the sterilization kettle is discharged into the sewage treatment system. After reaching the set time, the sterilization is completed. When sterilization is complete, a buzzer will sound to inform the operator that sterilization is complete. At this time, open the front door of the sterilizer, and the exhaust gas in the sterilizer will enter the exhaust gas treatment system through the air duct.