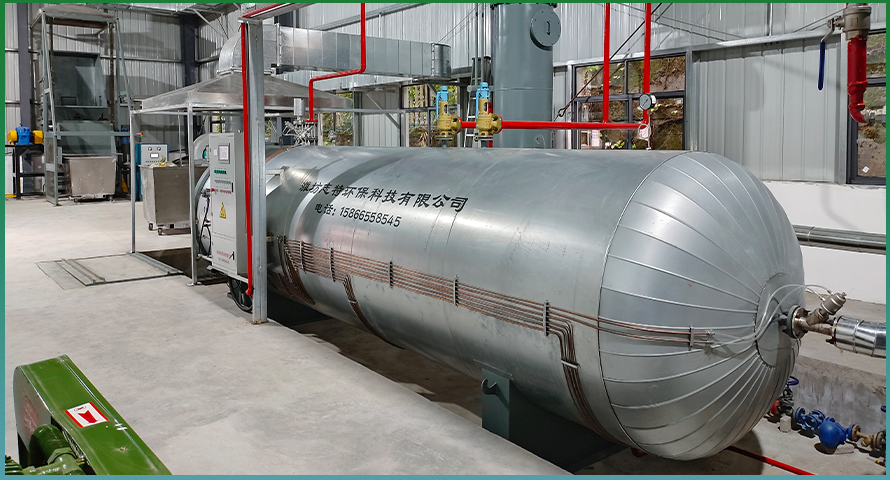

High temperature steam disinfection equipment for medical waste

Equipment introduction

High temperature steam sterilization (wet heat sterilization) is a kind of thermal sterilization. Under the influence of high temperature and high humidity, pathogenic microorganisms cause irreversible denaturation and solidification of proteins and enzymes, which leads to the death of microorganisms. So as to achieve the purpose of killing microorganisms. The high temperature steam sterilization process of medical waste takes high temperature saturated steam as the working medium, and uses its strong penetrating power to penetrate deep into the inside of the sterilized articles and release the latent heat contained in the steam, so that the sterilized articles quickly heat up to the sterilization temperature and maintain for a period of time, so that the protein in the bacteria solidify and denature, thus killing all microorganisms including bacterial spores.

Sterilization process

Charge:

The medical waste is poured into the sterilization car specially equipped with the sterilizer through the feeding machine, and then the sterilization car is transported to the sterilizer. After the number of sterilization cars in the sterilizer reaches the set value, close the front door and wait for sterilization treatment. Note: The front and back doors of the sterilizer cannot be opened at the same time. Once the program is running or there is pressure in the chamber of the sterilizer, it is not possible to open or close the door to ensure personal and equipment safety.

Sterilization treatment:

After the front door is closed, PLC gives instructions to the sterilizer to start running the sterilizer's preset sterilization program and carry out sterilization treatment. After entering the sterilization stage, the system automatically timing to ensure the sterilization intensity. In the sterilization stage, the steam main valve and steam auxiliary valve will be opened and closed according to the real-time temperature in the sterilization kettle. Once the temperature in the sterilization kettle is lower than the set sterilization temperature, the steam auxiliary valve will be opened to enter the steam for heating. When the temperature in the sterilization kettle is lower than the set temperature of 1℃ (configurable), the steam main valve will be opened to enter a large amount of steam for heating. When the temperature in the sterilization kettle is higher than the set sterilization temperature, the steam main valve and auxiliary valve are closed, which not only ensures the sterilization temperature but also avoids the steam waste caused by excessive temperature. When the sterilization time reaches the set time, the system moves to the post-vacuum drying stage.

The sterilization parameters are as follows (the purpose of the B-D test is to test the air exclusion effect or the vacuum performance to ensure the sterilization effect during normal sterilization) :

content | sterilizer | |

Sterilization disposal parameter | B-D test parameters | |

Sterilization temperature (℃) | 134 | 134 |

Sterilization pressure (kPa) | 220 | 220 |

Sterilization time (Min) | 45 | 4 |

Discharge:

After the sterilization treatment, the back door automatically opens, the sterilization car is launched, and then the sterilization car is transported to the discharge locomotive basket, which will pour the waste into the crusher for crushing treatment.

Technical advantages:

● The feeding of medical waste is mechanized and automated to reduce the direct manual operation.

● The feed car is also used as a container for medical waste in the sterilization room during the steam treatment process. The steam evenly penetrates and heat conducts during the treatment process. The material and structure can withstand the temperature and pressure changes during the steam treatment process.

● The feed port is air-tight and equipped with pumping equipment, and the feed and crushing run under the set negative pressure.

● Steam nozzle layout in the sterilization room ensures uniform temperature field in the sterilization room.

● Maintain its normal working state within the range of ± 10% of rated voltage.

● The inner cavity and door of the equipment are made of materials that are resistant to corrosion and can ensure continuous use in contact with water and water vapor. Generally, stainless steel is used.

● The door of the feed port and the discharge port can meet the requirements of the equipment working pressure on the sealing performance; An interlock device should be set up. When the door is not locked, the high-temperature steam treatment equipment cannot be heated or pressurised. The door cannot be opened before the end of the steam treatment cycle, and it should be open normally when the equipment is fed, discharged and maintained.

● The vacuum degree in the sterilization room should not be less than 0.08MPa, and the number of cycles of vacuum and steam filling is not less than 3 times; Ensure that the air discharge rate of sterilization room is not less than 98% after pulsating vacuum.