Equipment introduction

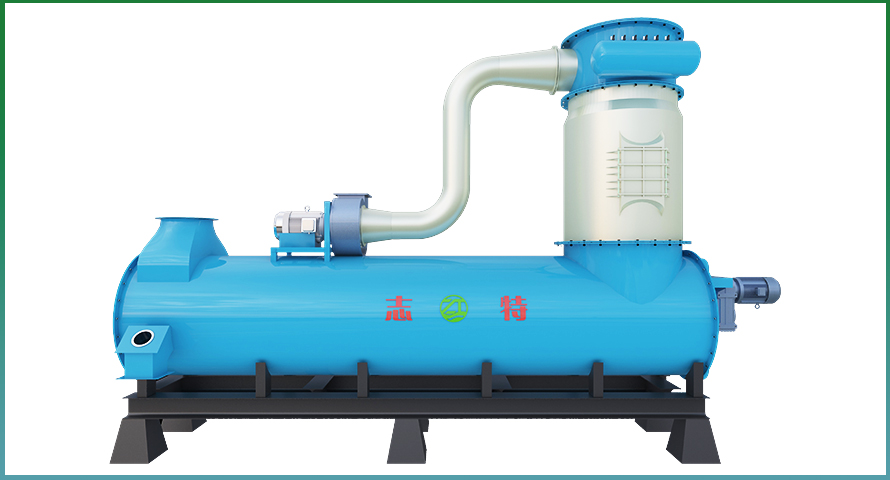

Air cooler integrates the functions of rapid air cooling, drying and dust removal of powder equipment in one. The equipment is mainly composed of automatic feeding spiral, rotating cooling cylinder, aggregate collection box, dust collection box, cyclone precipitator and other functional components.

The cold machine is widely used in the rapid cooling and drying of the materials after sterilization of sick pigs, sick cows, sick chickens, rabbits and other sick animals, and quickly remove the dust and trace odor of the materials after sterilization. The equipment can quickly dry and cool the materials after the high-temperature production of various sick and dead animals, and the rapid cooling and drying treatment of high temperature materials can be completed in 0.5-1 minutes (continuous cooling and drying treatment). The finished materials are about 25-35℃ according to the difference of the initial materials and the ambient temperature (discharging materials are normal temperature materials); The equipment is equipped with dust collection box, dust pipe, dust collector, dust fan, etc., which can effectively remove all kinds of dust generated in the process of material mixing and cooling and a small amount of uncollected odor generated in the process of preprocessing sterilization.

Product characteristics

1. Simple structure, easy to use and maintain: the whole machine adopts an integrated structure, the bottom is cooling, the upper part is dust removal. When in use, the air cooler feed equipment and air cooler body screw docking, air cooler outlet and discharge equipment docking, press a key to start, the material automatically into the air cooler, and under the mixing of the air cooler and the strong convection of the cold air, rapid cooling and drying, dust removal fan automatically quickly suction the dust and a small amount of odor inside the air cooler to the dust removal pipe dust treatment. After the process is completed, the material is automatically discharged from the discharge port, and the equipment control box is equipped with PLC and DCS system interface. After the operation is completed, the central control system will prompt the operation to be completed, and the operator will press the discharge button to automatically discharge the material, which is convenient and safe.

2. Short processing time, good cooling effect and energy saving: the air-cooled rotating cylinder matches the feeding speed of the feeding equipment, and the material is quickly dispersed under the action of the air-cooled rotating cylinder after feeding, improving the contact area between the high-temperature material and the cold air to ensure the rapid cooling and drying of the material.

3. The air cooling medium adopts the low temperature cold air after the normal temperature air blast, and the air cooling method is the rapid contact of the self-heating cold air and the high temperature material to dry and cool, without providing other cold source or thermal insulation and cold protection structure. Ensure cooling effect while reducing energy consumption.

4. Simple operation, intelligent system integrated control: The equipment field control cabinet reserved DCS and PLC control system interface, through the PLC control system to set the operating parameters, according to the equipment preset workflow without manual intervention, to achieve the function of automatic operation, the operating system includes intelligent operable display module, can display the operating status and operating parameters of the equipment in real time, the user can according to the processing capacity of the preceding equipment, Adjust the set parameters in real time, and has the function of one-key start and one-key shutdown. After the equipment is officially started, the one-key start function key enters the automatic operation state. Without manual operation, the material is automatically fed, the material is automatically dispersed quickly, the air is automatically sent into the cold air, and the dust and odor are automatically absorbed and processed.