Equipment introduction

Farm high-temperature harmless treatment equipment, also known as small high-temperature made sets equipment, mainly for large and medium-sized pig farms to provide use, can quickly deal with various types of sick pigs, fetal clothing, etc., can also be used for other large and medium-sized animal farms, For example, large and medium-sized cattle farms, large and medium-sized sheep farms, large and medium-sized chicken farms, large and medium-sized duck farms, large and medium-sized goose intestines, large and medium-sized rabbit farms, such as the harmless treatment of dead animals.

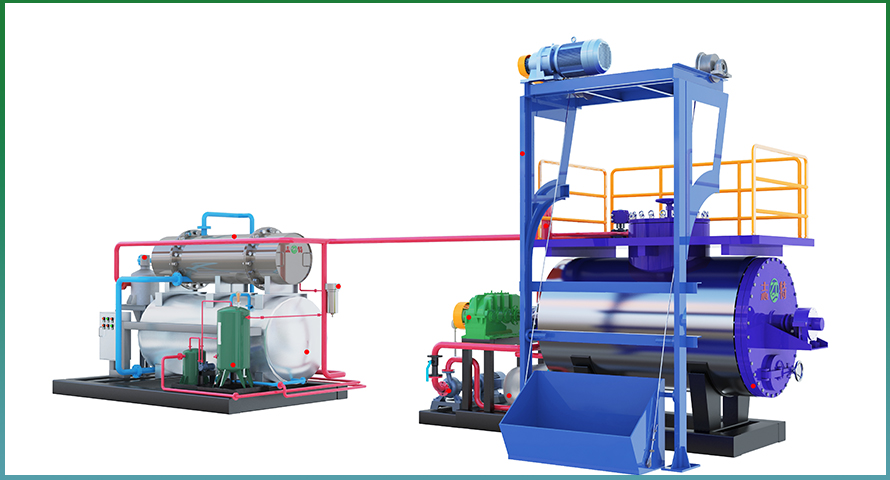

This set of equipment is mainly composed of automatic elevator, pre-crushing processor, feed screw, chemical machine, vacuum cooling system, discharge screw, oil press, electrical control cabinet and so on. When in use, put the sick and dead pigs into the lifting bucket of the automatic lifting equipment, press the start button, the lifting bucket will automatically rise and lift the sick and dead pigs to the pre-crusher, and automatically open the feed door of the pre-crusher, reverse the lifting bucket, put the sick and dead pigs into the feed door of the pre-crusher, the pre-crusher and feed screw will automatically open, and the sick and dead pigs will be crushed and preprocessed. At the same time, the heating equipment of the chemical machine will automatically start, and the chemical machine will start to heat up. After the sick and dead pigs are broken by the precrusher and the feed screw, the precrusher will stop working, and the feed screw will stop working 5 minutes later, and the chemical machine will automatically start to keep heat after reaching the set temperature. After 1-1.5 hours of heat preservation and pressure protection (time can be adjusted), the vacuum condensing system starts to work, and the chemical machine starts to discharge the material. The chemical machine automatically sends the dry material to the discharge port of the chemical machine, and the material is sent to the designated place or the oil press for further processing through the discharge screw of the chemical machine.

The whole set of equipment is equipped with automatic control electrification system, and the specific operation mode is selected by the on-site operator or manual operation mode according to the on-site situation.

Product characteristics

1. Safe closure: The processing process is closed and reliable, thorough elimination, in line with biosafety requirements, and in line with epidemic prevention requirements;

2. Ecological and environmental protection, equipped with gas purification system, exhaust gas standards, no secondary pollution;

3. Easy operation and maintenance, high degree of equipment automation, low labor intensity;

4. Economical and reliable, low equipment investment, low operating cost, low failure rate, low maintenance cost;

5. Fast heating, high pressure, saving running time.

Equipment parameter

(The dimensions can be redesigned according to the site, please contact the sales staff for detailed parameter configuration) :

Model number | Inside tank size (mm) | Tank volume | Handling capacity | Chemical machine main power | Chemical machine spindle speed | Dimensions of the chemical machine |

ZT-HZJ/ST-0.5 | Φ1000x1600 | 1.2m³ | 0.5T/batch | 7.5kw | 20R/min | 3000x1400x1700 |

ZT-HZJ/ST-1 | Φ1100x2200 | 2m³ | 1T/batch | 11kw | 20R/min | 3600x1500x1800 |

ZT-HZJ/ST-2 | Φ1300x3000 | 4m³ | 2T/batch | 15kw | 21R/min | 4400x1700x2000 |

ZT-HZJ/ST-3 | Φ1400x3300 | 5m³ | 3T/batch | 18.5kw | 21R/min | 4700x1800x2100 |